描述

High Consistency Polypropylene

Melt Blown Cartridge

- Graded Pore Structure Enhances Dirt Holding Capacity

- E-core, an Extruded Fibrous Core, Provides Excellent Strength

- Unique Proprietary Process

- Easy and Safe Cartridge Incineration and Disposal

- All Polypropylene Construction

- Free of Surfactants, Binders, and Adhesives

- NSF Certified

- Plastic and Metal Spring Assembly End Configurations Available

Specifications

Performance Specifications

Filter grades

- 1, 3, 5, 10, 20, 30, 50, 75 micron (μm)

Maximum differential pressure

- 3.45 bard (50 psid) @ 20 °C (68 °F)

- 1.72 bard (25 psid) @ 60 °C (140 °F)

Recommended change-out differential pressure1

- 2.4 bard (35 psid)

Food and Water Contact Use

- Please contact Pall Corporation to verify that the product conforms to your national legislation and/or regional regulatory requirements for water and food contact use.

Purity

- Cartridges do not use surfactants, anti-static agents, binders, and adhesives.

Product Specifications

Materials of construction

- Filter media: Polypropylene

- End caps2: Polypropylene

- Extended core2: Stainless steel

- Extruded core: Polypropylene

- Gaskets/O-rings2:

- Silicone elastomer

- nitrile

- fluorocarbon elastomer

- EPDM

- Santoprene3

Dimensions (nominal)

- Outside diameter: 6.4 cm (2.5 in.)

- Inside diameter: 2.7 cm (1.07 in.)

- Lengths:

- 24.8 cm (9.75 in.)

- 25.1 cm (9.875 in.)

- 25.4 cm (10 in.)

- 49.5 cm (19.5 in.)

- 50.2 cm (19.75 in.)

- 50.8 cm (20 in.)

- 74.3 cm (29.25 in.)

- 74.9 cm (29.5 in.)

- 75.6 cm (29.75 in.)

- 76.2 cm (30 in.)

- 99.1 cm (39 in.)

- 102 cm (40 in.)

- 127 cm (50 in.)

1Provided that the maximum differential pressure is not exceeded based on temperature limits defined above.

2 These components are not NSF certified.

3 Trademark of Exxon Mobil Corporation.

Performance

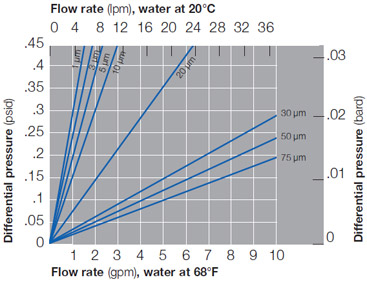

Typical Flow vs. Differential Pressure for Application Sizing

Unit conversion: 1 bar = 100 kPa

Flow rate is for a 25.4 cm (10 in.) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Type

Filter Cartridges

Application

Waste reclaim, Wet etch & cleans

Ordering Information

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Example Part Number: CLR 10 20 DOE S ( See bold references in tables below)

Part Number:

CLR < Filter grade code from Table 1 > < Cartridge length code from Table 2 > < End configuration code from Table 3 > < Gasket/O-ring material code from Table 4 >

4 Based on typical application usage.

Example Part Number: CLR 10 20 DOE S ( See bold references in tables below)

Part Number:

CLR < Filter grade code from Table 1 > < Cartridge length code from Table 2 > < End configuration code from Table 3 > < Gasket/O-ring material code from Table 4 >

Table 1 - Filter grades

| Code | Filter grades (μm)4 |

| 1 | 1 |

| 3 | 3 |

| 5 | 5 |

| 10 | 10 |

| 20 | 20 |

| 30 | 30 |

| 50 | 50 |

| 75 | 75 |

Table 2 - Cartridge lengths

| Code | Cartridge lengths (cm/in.) nominal |

| 9.75 | 24.8/9.75 |

| 9.875 | 25.1/9.875 |

| 10 | 25.4/10 |

| 19.5 | 49.5/19.5 |

| 19.75 | 50.2/19.75 |

| 20 | 50.8/20 |

| 29.25 | 74.3/29.25 |

| 29.5 | 74.9/29.5 |

| 29.75 | 75.6/29.75 |

| 30 | 76.2/30 |

| 39 | 99.1/39 |

| 40 | 102/40 |

| 50 | 127/50 |

Table 3 - End configurations

| Code | End configurations |

| Blank | DOE industrial (no end caps) |

| DOE | DOE with elastomer gasket seals & end caps |

| H21 | DOE, Santoprene gasket seal |

| 1X | DOE industrial, 2.54 cm (1 in.) stainless steel extended core |

| M3 | SOE flat closed end, external 222 O-rings (retrofits other manufacturers' Code 0)5 |

| M6 | SOE flat closed end, external 226 O-rings (retrofits other manufacturers' Code 6) 5 |

| M7 | SOE fin end, external 226 O-rings (retrofits other manufacturers' Code 7) 5 |

| M8 | SOE fin end, external 222 O-rings (retrofits other manufacturers' Code 5)5 |

| M18 | SOE flat closed end, external 222 O-ring |

| XK | SOE plastic spring assembly, saw cut end |

| SI | SOE metal spring/polypropylene cap, saw cut end |

Table 4 - Gasket/O-ring materials

| Code | Gasket/O-ring materials |

| S | Silicone |

| N | Nitrile |

| E | EPDM |

| V | Fluorocarbon elastomer |

4 Based on typical application usage.

5 For details, contact Pall Corporation.

Segments

Photovoltaics, Photovoltaics

检查

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.