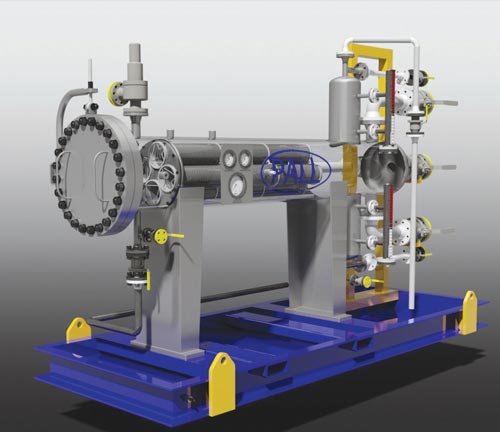

Liquid/Liquid Coalescer Technology Available as a Rental Skid: Simplex 9 Element Coalescer Skid (Skid can be converted to a filter)

描述

For more than 70 years Pall Corporation has been solving complex contamination problems across the refining, petrochemical and oil and gas industries. By applying our advanced filtration and separation technologies directly to the problem, we’re able to help operators reduce maintenance costs and minimize unscheduled shutdowns. Pall’s proprietary polymeric coalescers efficiently break stable emulsions. Common applications of our liquid-liquid coalescer filter skid units include water from refinery fuels, caustic from fuels, hydrocarbon from rich amine or sour water.

Features

- Flow capacity up to 160 m3/h (700 USGPM) (24,000 bbl/day)

- Fully valved and piped on skid (inlet/outlet, clean and dirty side vents and drains)

- Local differential pressure gauge

- Local pressure gauge

- Local temperature gauge

- Local level gauge

- PSV installed

- Integrated points for influent and effluent samples

- NORSOK compliant vessel

- NACE compliant for sour service

- Fully enclosed sump area to low point

- Vent line to sump

- All lines to skid edge

- Skid frame has options for single point lift/fork lift truck

- Full set of transportation blinds

Applications

- Remove water from refinery fuels including LPG and gas oil

- Remove hydrocarbon from sour water or rich amine

- Remove caustic from refinery fuels

- Can be operated as a water washer

- Will accept the following Pall coalescer technologies: PhaseSep, AquaSep Plus, AquaSep XS, and AquaSep EL

- Remove water from fuels to protect catalyst beds

- Remove water from steam stripped diesel

Specifications

- Mobile skid unit dimensions (L x W x H): 3.9 m (153.5 in) x 1.5 m (59 in) x 2.6 m (102.4 in).

Can be shipped via standard flatbed truck. - Skid weight: Dry – 3500 kg, Full of Water – 3900 kg

- Vessel design code: EN13445/ PED Module G Cat. 4/CE marked

- Piping design: ASME B31.3

- Design pressure: 34 bar (493 psi)

- Design temperature: 80°C (176°F)

- Inlet/outlet 4” RFWN flange

- Coalescer vessel: 1 Removable 9 x 101.6 cm (40 in) AquaSep®/PhaseSep® Coalescer plate assembly

- Full documentation package and drawings available

Materials of Construction

- Vessel: 316L Stainless steel

- Piping: 316L Stainless steel

- Base frame: Carbon steel painted

- Housing closure gasket: 316L SW graphite filled

1 For complete details, request a design package.

|

|

Type

Segments

检查

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.