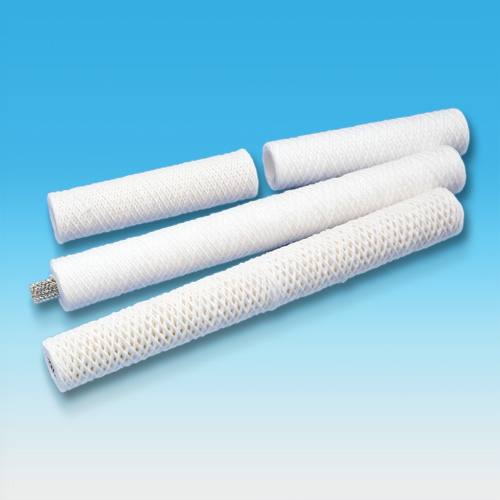

Reliable, Consistent Filtration Performance From Each Cartridge

- Graded pore structure for efficient removal of a wide range of particle sizes

- Cost savings from long service filter life

- Diverse range of removal ratings

- Wide chemical compatibility

- Suitable for liquid and gas filtration

- High contaminant-holding capacity

- Cartridges fit into most standard housings

- Various cartridge sealing options

- Numerous cartridge configurations

- Manufactured under ISO 9001 quality system

- Chemicals: polishing of chemical solutions, bulk industrial chemicals, solvents, acids, bases, monomers, process and cooling water

- Magnetic Coatings: audio, video & computer tape, floppy discs, computer hard discs, solvents

- Photographic: photo emulsions, chemicals, wash & rinse water

- Oil Production: well completion fluids, water flood

- Air & Gas: compressed air, instrument air, most gases including nitrogen, hydrogen, helium, freon, most corrosive gases

- Other: solution mining, deep well disposal, paint, ink & coatings, lubricating oils, electropolishing solutions, plating solutions, pigments & dyes, cleaning fluids, adhesives.

Materials of construction

Filter media

Bleached cotton, standard cotton, natural cotton, glass fiber, heat purified glass fiber, premium polypropylene, standard polypropylene, rayon, polyester, nylon, acrylic, polyphenylene sulfide (PPS).

Center corePolypropylene, electrolytic tin plated steel (ETP), 304 stainless steel, 316 stainless steel.

Core cover optionUsed to control fiber migration; compatible with existing fiber. Materials include polypropylene, nylon, fiberglass, and polyester.

End treatment optionAdditional fiber migration control; compatible with existing fiber material.

Dimensions (nominal)| Outside diameter: | 5.1 cm (2 in), 6.0 cm (2.375 in), 6.4 cm (2.5 in), 6.7 cm (2.625 in) optional |

| Inside diameter: | 2.5 cm (1 in) |

| Lengths1: | 24.8 cm (9.75 in), 25.4 cm (10 in), 49.5 cm (19.5 in), 50.8 cm (20 in), 74.9 cm (29.5 in), 76.2 cm (30 in), 99.1 cm (39 in), 100.3 cm (39.5 in), 102 cm (40 in), 125.7 cm (49.5 in), 127 cm (50 in) |

1 For additional length requirements, consult your Pall representative.

Filter grades

0.5, 1, 2, 3, 5, 7, 10, 15, 20, 25, 30, 40, 50, 75, 100, 150, 200, 250, 300, 350μm

Maximum temperature rating

See Material Selection Guide (Under Specifications)

Material Selection Guide

| Filter Medium | Premium Cotton | Premium Polypropylene | Rayon | Polyester |

| Maximum Temperature with metal core with polypropylene core | 149°C (300°F) 60°C (140°F) | 93°C (200°F) 60°C (140°F) | 149°C (300°F) 60°C (140°F) | 121°C (250°F) 60°C (140°F) |

| Compatibility with: Potable Liquids, Water | Excellent | Excellent | Good | Good |

| Organic Solvents | Excellent | Good | Excellent | Excellent |

| Oils | Excellent | Fair | Excellent | Good |

| Organic Acids | Good | Excellent | Good | Good |

| Alkalies | Good | Excellent | Good | N/R |

| Oxidizing Agents | Fair | Poor | Fair | Good |

| Steam, Non-Continuous | N/R | Fair | N/R | Fair |

| Strong Inorganic Acids | N/R | Excellent | Poor | Fair |

| Dilute Inorganic Acids | Fair | Excellent | Fair | Good |

| Microorganism Resistance | Poor | Excellent | Poor | Excellent |

| Filter Medium | Glass Fiber | PPS | Nylon | Acrylic |

| Maximum Temperature with metal core with polypropylene core | 399°C (750°F) 60°C (140°F) | 191°C (375°F) 60°C (140°F) | 121°C (250°F) 60°C (140°F) | 93°C (200°F) 60°C (140°F) |

| Compatibility with: Potable Liquids, Water | Poor | Excellent | Poor | Good |

| Organic Solvents | Excellent | Excellent | Excellent | Good |

| Oils | Excellent | Excellent | Excellent | Good |

| Organic Acids | Excellent | Excellent | Fair | Good |

| Alkalies | Poor | Excellent | Excellent | Fair |

| Oxidizing Agents | Excellent | Poor | Fair | Good |

| Steam, Non-Continuous | N/R | Fair | Fair | Poor |

| Strong Inorganic Acids | Excellent | Excellent | N/R | Good |

| Dilute Inorganic Acids | Excellent | Excellent | Poor | Excellent |

| Microorganism Resistance | Excellent | Excellent | Excellent | Excellent |

N/R = Not Recommended

Pall Part Number = [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11]

Table 1

| Code | Type of service |

| Blank | Liquid |

| G | Gas/air |

Table 2

| Code | Filter medium |

| C | Bleached cotton |

| E | Polyester |

| F | Glass fiber |

| G | Heat purified glass fiber |

| U | Premium polypropylene |

| P | Standard polypropylene |

| RT | PPS |

| N | Nylon |

| O | Acrylic |

| R | Rayon |

| NC | Natural cotton |

| SC | Standard cotton |

Table 3

| Code | Filter grades (μm) |

| 0.5 | 0.5 |

| 001 | 1 |

| 002 | 2 |

| 003 | 3 |

| 005 | 5 |

| 007 | 7 |

| 010 | 10 |

| 015 | 15 |

| 020 | 20 |

| 025 | 25 |

| 030 | 30 |

| 040 | 40 |

| 050 | 50 |

| 075 | 75 |

| 100 | 100 |

| 150 | 150 |

| 200 | 200 |

| 250 | 250 |

| 300 | 300 |

| 350 | 350 |

Table 4

| Code | Outside diameter (nominal) |

| A | 2.5 in (standard) |

| B | 2.625 in |

| D | 2 in |

| R | 2.375 in |

Table 5

| Code | Integrally wound |

| Blank | For under 10 inches |

| W | All cartridges over 10 inches are integrally wound |

Table 6

| Code | Cartridge lengths nominal (cm/in) |

| 9.75 | 24.8/9.75 |

| 10 | 25.4/10 |

| 19.5 | 49.5/19.5 |

| 20 | 50.8/20 |

| 29.5 | 74.9/29.5 |

| 30 | 76.2/30 |

| 39 | 99.1/39 |

| 39.5 | 100.3/39.5 |

| 40 | 102/40 |

| 49.5 | 125.7/49.5 |

| 50 | 127/ 50 |

Table 7

| Code | Core material |

| A | 304 stainless steel |

| S | 316 stainless steel |

| T | Electrolytic tin plated steel (ETP) |

| U | Polypropylene |

Table 8

| Code | Core cover |

| Blank | None |

| C | Compatible with and equal to resistance of filter medium |

Table 9

| Code | End treatment |

| Blank | None |

| E | Compatible with and equal to resistance of filter medium |

Table 10

| Code | Extended core |

| Blank | None |

| EC1A | 304 stainless steel |

| EC1S | 316 stainless steel |

| EC1T | Electrolytic tin plated pteel (ETP) |

| EC1U | Polypropylene |

Table 11

| Code | Packaging |

| Blank | Bulk |

| 1PK | Individually wrapped |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.