The Pall SepraSol™ Plus Liquid/Gas Coalescer removes liquids and solids from high flow gas streams that contain high concentrations of liquids.

Pall Corporation’s staff of research scientists and engineers have designed these coalescers that change the way gas streams are conditioned.

The SepraSol Plus media can process several times more liquid per unit area of media than conventional media and often eliminates the need for upstream bulk separation equipment like mist eliminators and vane separators.

The SepraSol Plus media is supplied in a large flow, high performance 6-inch diameter cartridge that can economically treat large gas flows in applications that require a high degree of protection from both solids and liquids including:

- Protecting compressors and turbines

- Removing lubrication oil, water, and compressor wear products from effluent gas streams

- Removing liquid aerosols from gases fed to amine sweetening and dehydration units to prevent foaming problems

- Protecting desiccant and catalyst beds

- Minimizing solution losses downstream of gas purification process units

- Cleaning dirty fuel gas to protect low Nox burners and fuel injection nozzles

- Controlling injection well plugging during gas flooding

Description

Liquid Influent Concentration – the key to coalescer performance

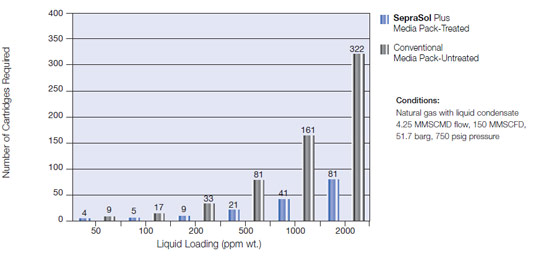

One major reason why coalescers do not function properly in the field is because of an underestimation of the liquid influent concentration to the coalescer. Simply stated, the more liquid charged to a coalescer system, the more coalescer media required. If the coalescer is challenged with too much liquid, significant quantities of liquid will become re-entrained in the effluent gas, and downstream equipment problems will continue to occur.

The Pall SepraSol Plus media is able to handle higher levels of liquid per unit area and requires significantly fewer cartridges to remove liquid and solids from gases. This is illustrated in Figure 1, which compares the SepraSol Plus liquid/gas coalescer with a conventional media pack. As the liquid load is increased, the number of cartridges required to remove the liquid also increases.

With conventional media packing, the cartridge requirement may become uneconomical once the liquid concentration gets above a few hundred ppmw. The SepraSol Plus liquid/gas coalescer economically removes liquids with a concentration in the thousands of ppmw, often eliminating the need for an upstream bulk separator.

Technical Information

| Nominal Cartridge Dimensions | |

| Part Number | CS604LGH13 (single open end) CS604LGBH13* (single open end) CS604LGDH13 (double open end) CS604LGBDH13* (double open end) |

| Outer Diameter | 152.4 mm (6") |

| Length | 1016 mm (40") |

| Surface Area | 2.6m2 (28 ft.2) |

* Amine compatible

| Performance Specification | |

| Solid Removal Rating* | 99.7% @ ≥ 0.3μm |

| Liquid Removal Ratings | .01ppm downstream liquids (LASE)** 1 ppb downstream liquids (CAGI)*** 99.999% efficient at 0.3 micron (DOP)**** |

| Temperature Rating | 82 ºC (180 ºF) 65 ºC (150 ºF) with water |

| Clean and Saturated Pressure Drop | Sized to your specification |

* Per sodium chloride challenge test

** Per the Pall Liquid Aerosol Separation Efficiency (LASE) Test

*** Per the modified ANSI/CAGI-400-1999 test procedure

**** Per the Di-Octyl Phthalate (DOP) test using a monodisperse 0.3 micron aerosol

Materials of Construction

- Resin bonded glass fiber SepraSol Plus coalescer media designed in a pack to handle large quantities of liquid

- Polymeric outer drainage layer to prevent liquid re-entrainment

- Oleophobic/hydrophobic treatment to improve liquid drainage, protect from liquid slugs and minimize saturated pressure drop

- Stainless steel metal support

Coalescer Technical Information

The SepraSol Plus Liquid/Gas Coalescer – no longer just for polishing

Before the development of the SepraSol Plus liquid/gas coalescer, high-efficiency liquid/gas coalescers were used specifically for polishing.Generally, if the liquid influent concentration was greater than a few hundred ppmw, a bulk separator such as a knock-out drum, mist eliminator, or vane separator was required upstream of the coalescer to remove large liquid droplets and a coalescer would be used to remove the small droplets (less than 5 micron).

As demonstrated below in Figure 1, the SepraSol Plus liquid/gas coalescer can handle high liquid loads, often eliminating the need for upstream bulk removal equipment. In addition to the benefits of our media, the SepraSolPlus liquid/gas coalescer also includes features that have been Pall coalescer standards for many years.

Oleophobic/hydrophobic Treatment

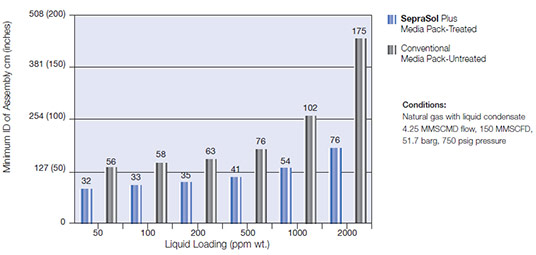

All of Pall’s SepraSol and SepraSol Plus liquid/gas coalescers receive the patented oleophobic/hydrophobic treatment. Chemically treating the coalescer lowers the surface energy of the media and promotes rapid drainage of the coalesced liquids. This significantly increases the amount of liquid per square foot of media the coalescer can handle.Added benefits to the chemical treatment include lower saturated pressure drop, which saves operating costs and rapid recovery from liquid slugs.

Figure 2 shows the effect of the benefits of both the oleophobic/hydrophobic treatment and the SepraSol Plus liquid/gas coalescer compared to a coalescer with conventional packing and no chemical treatment.

Note: under the process conditions stated, the SepraSol Plus liquid/gas coalescer with chemical treatment requires a significantly smaller assembly under maximum liquid loading conditions than the untreated coalescer with the conventional pack design. Assembly diameter is directly related to the overall installation cost.

Liquid Loading Comparison

Figure 1

Cartridge Requirement Comparison of SepraSol Plus Liquid/Gas Coalescer Media Pack versus Untreated Conventional Media Pack

Figure 2

Assembly Diameter Comparison of SepraSolPlus Media Pack versus Untreated Conventional Media Pack

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.