The same problem can occur when attempting to separate oil from water. The presence of surfactants also leads to disarming of the coalescer. Pall’s AquaSep coalescer will efficiently separate water from a hydrocarbon stream without disarming.

Common Sources of Surfactants in Hydrocarbon and Chemical Processes

- Sulfur compounds

- Organic acids

- Well treating chemicals

- Anti-static chemicals

- Detergents

- Corrosion inhibitors

- Chemical additives

Coalescer Information

The Pall AquaSep coalescer is a multiple stage system. It first removes particulate matter, then coalesces and separates the dispersed phase liquid from the continuous phase liquid.

For removal of water from hydrocarbons, an AquaSep coalescer will remove entrained water to a level of below 15 ppmv over a wide range of conditions:

- Inlet water concentration as high as 3% water by volume (i.e., 30,000 ppmv.)

- Interfacial tension as low as 3.0 dyne/cm.

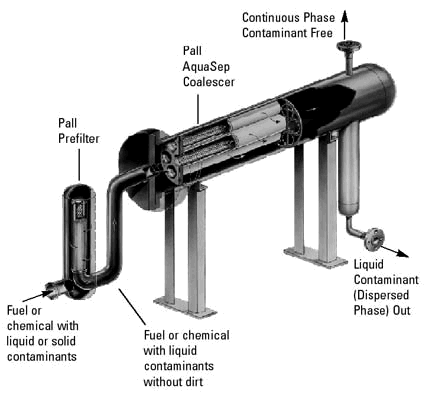

For removal of oil from water, an AquaSep Plus coalescer will remove free oil from water over a wide range of conditions in the horizontal configuration.

Products in this datasheet may be covered by one or more patents, including EP 930,926; US 5,443,724; US 6,332,987.Liquid/Liquid Coalescer Elements

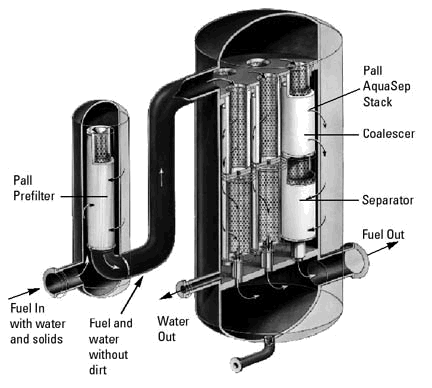

Stage 1: Prefiltration

Due to the fine pore structure of this coalescer medium, Pall recommends that a prefilter be installed upstream of the coalescer assembly to properly control particulate matter in the liquid stream. Installing a prefilter significantly extends the life of the coalescer and reduces particulate concentration in the filter effluent to meet solids specifications.To maximize the service life of AquaSep Plus coalescers, each coalescer is constructed with an integral prefilter.

Stage 2: Coalescence

The hydrocarbon and water mixture enters the coalescing element and flows inside to outside (see Figure 1). This is where small droplets of dispersed phase liquid come together, or coalesce, as the mixture moves through the depth of Pall’s specially formulated coalescer medium.Stage 3: Separation

In separating water from fuel, water-free fuel and large water droplets flow toward the separator located directly below the coalescer stage. Flow is outside to inside (see Figure 1). The separator medium is hydrophobic, which prevents water from entering the separator. Only water-free fuel flows through the separator. Water and fuel are removed by separate drain connections.In separating oil from water, a settling zone is designed downstream of the coalescer. In the settling zone, the large coalescer droplets are separated due to gravity (see Figure 2).

Benefits

Continuously Efficient in Liquid Separation and Particle Removal for Improved Fluid Quality and Value

The effective liquid separation and the particulate removal abilities of the AquaSep Plus coalescer system significantly reduces off-spec product incidents, thereby saving reprocessing and transportation costs.

- Low Cost Liquid Separation and Solids Removal

Due to AquaSep Plus coalescer’s longer life and superior liquid separation efficiency, the overall cost of liquid separation is low especially when compared to other, less efficient, methods. The integral prefilter within the AquaSep Plus coalescer maximizes element service life. - Does Not Disarm; Increases Service Life

Pall’s specially formulated medium coalescer contains no glass fiber and does not disarm in the presence of surfactants. This results in longer service life than conventional coalescers. The prefilter stage removes particulates and also extends the filter service life. - High Performance Design Results in Smaller Assembly Size

The high performance AquaSep Plus coalescer stack design promotes an even flow distribution permitting a high rate of flow. As a result, fewer coalescer cartridges are required to efficiently remove water from fuel. This results in a small economic assembly size.

Figure 1: Pall AquaSep Plus Liquid/Liquid Coalescer System

Lower Disposal and Maintenance Costs

The long, useful life of the AquaSep Plus cartridges, is obtained from Pall’s specially formulated non-disarming high voids volume media that is properly protected by Pall prefilters. Overall results are fewer cartridge changeouts for low maintenance and disposal costs.Unique Stack Design

Pall’s coalescer element is stacked on top of a separator element. This design optimizes the flow distribution from the coalescer to the separator, ensuring that each separator has an equal flow. In conventional two-stage systems, the separators are located at different distances from the coalescer, causing an unequal distribution of flow to the separator. These conventional two-stage systems require several coalescer elements for each separator. Pall’s stack design results in overall smaller assembly size and a longer coalescer/separator life.Fluid Compatibility

Pall’s AquaSep Plus liquid/liquid coalescer is compatible with refined products including:- All gasolines

- Diesel

- Kerosene

- Lube oils

- Aromatics

- Petrochemicals

-

LPG

Figure 2: Pall AquaSep Plus Liquid/Liquid Separation System with Coalescer in a Horizontal Housing

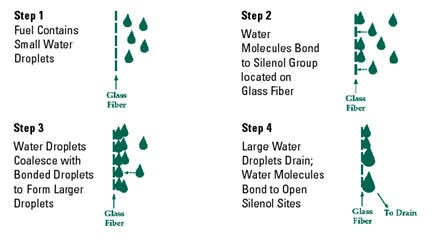

Mechanism of Coalescing with Conventional Glass Medium

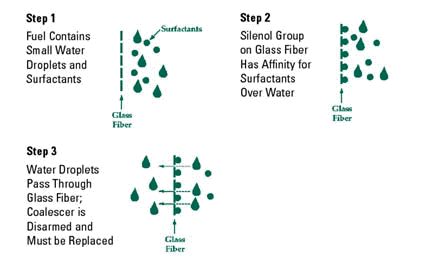

One of the biggest operational problems for conventional liquid/liquid coalescers is disarming. When a liquid/liquid coalescer is performing efficiently, water molecules bond with components on the glass fiber called a silenol functional group. The water molecules that collect on the glass fiber coalesce with incoming water molecules to form a large droplet, which will eventually become heavy enough to drain from the coalescer. In an efficiently operating coalescer, once a droplet has fallen from an active site, the coalescing process repeats (see Figure 3).

Figure 3: Mechanism for Coalescing

Disarming occurs when surfactants bond with the silenol. The silenol group has a greater affinity for surfactant molecules than for water molecules. As the surfactant molecules bond to the glass fibers, the water molecules pass quickly through the medium (see Figure 4). This greatly reduces water removal efficiency, increasing the probability of a product quality problem, and short coalescer service life, which, in turn, results in frequent changeout and increased disposal costs of coalescer filter elements.

Figure 4: Mechanism for Disarming

Performance Claims and Specifications

| Maximum Temperature: | 66°C/150°F |

| Initial Pressure Drop: | 0.14 bard/2 psid |

| Recommended Changeout: | 1.03 bard/15 psid |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.