Pall Aerolith S filter material is a further development of the well-known Pall® product Aerolith with improved properties. Composed of selected high-quality ceramic raw materials, the alumosiliceous filter material Aerolith S is produced in a controlled production process as a cylinder, candle, or tile. The special merits of Aerolith S filter elements are the higher mechanical stability as well as an improved pH resistance in the alkaline range. Due to the porous labyrinth structure with high particle storage capacity, this liguid gas filter element is well suited for depth filtration applications up to temperatures of 700°C.

General Information

- Porous Aerolith S ceramic is approved for the utilization in drinking water according to German regulations DVGW W270 and the KTW recommendation.

- Aerolith S filter elements can be machined using hard metal tools.

- Ceramic elements are to be handled with care.

- Elements can be easily glued using commercial glues, which Pall can supply. Consideration must be paid to operating temperature and chemical resistance.

- Pall can supply a variety of element fixing systems.

Chemical Resistance3

Aerolith S filter elements are resistant against most acids, saline solutions, and organic solvents, liquid or gaseous. It does not resist hydrofluoric acid. Aerolith S filter elements are resistant up to pH 10 in the alkaline range.

3 As end use conditions can vary, it is the users responsibility to verify compatibility with their specific use conditions

Cylinders

| • Particle filtration of Liquids | Acids, water and alcohol |

| • Particle filtration of Gases | Process gases, mixed gas, air, sewer gas, natural gas, and liquid gas |

| • Coalescer | Compressed air, nitrogen and carbon dioxide |

| • Storing Media | Water, colour and ink |

| • Vacuum Lance | Retention of fire extinguishing powder |

Plates

| • Nutsches | Mud thickening |

| Aerolith S (AES) | Cylinders / Plates | |||

| AES 05 | AES 10 | AES 20 | AES 30 | |

| Filtration of Gases1 | < 1 μm | 1.5 μm | 2.5 μm | 5 μm |

| Porosity | 40 % | 40 % | 40 % | 40 % |

| Material Density | 1.5 g/cm3 | 1.5 g/cm3 | 1.5 g/cm3 | 1.5 g/cm3 |

| Specific Permeability | 25 10-13 m2 | 50 10-13 m2 | 100 10-13 m2 | 250 10-13 m2 |

| O-Ring Strength Compression | > 10 MPa | > 10 MPa | > 9 MPa | > 8 MPa |

| Maximum Temperature Resistance2 | 700 °C | 700 °C | 700 °C | 700 °C |

| Expansion Co-efficient (25 - 200 °C) | 3.0 10-6 /K | 3.0 10-6 /K | 3.0 10-6 /K | 3.0 10-6 /K |

| Expansion Co-efficient (25 - 700 °C) | 4.7 10-6 /K | 4.7 10-6 /K | 4.7 10-6 /K | 4.7 10-6 /K |

| 70 / 40 mm | 70 / 40 mm | 70 / 40 mm | 70 / 40 mm | |

1 PSG Retention efficiency test 99.98%

2 Depending on operating conditions

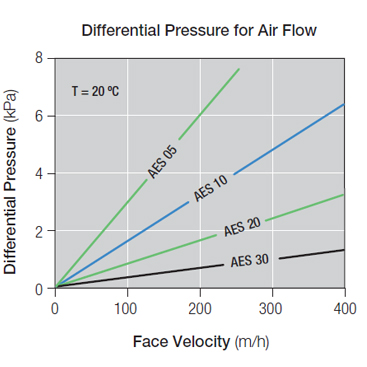

Flow vs Differential Pressure

| Part Number | Aerolith (AES) | Type | Do / Di (mm) | Length (mm) | Area (m2) | Weight (kg) |

| 89580483 | Cylinder | 10 | 40 / 20 | 80 | 0.010 | 0.1 |

| 89580051 | 20 | 40 / 20 | 80 | 0.010 | 0.1 | |

| 89580480 | 10 | 60 / 40 | 500 | 0.095 | 1.2 | |

| 89580054 | 30 | 60 / 40 | 500 | 0.095 | 1.2 | |

| 89580476 | 5 | 60 / 40 | 1000 | 0.188 | 2.4 | |

| 89580477 | 10 | 60 / 40 | 1000 | 0.188 | 2.4 | |

| 89580478 | 20 | 60 / 40 | 1000 | 0.188 | 2.4 | |

| 89580053 | 30 | 60 / 40 | 1000 | 0.188 | 2.4 | |

| 89580452 | 5 | 70 / 40 | 1000 | 0.220 | 3.9 | |

| 89452208 | 10 | 70 / 40 | 1000 | 0.220 | 3.9 | |

| 89580050 | 20 | 70 / 40 | 1000 | 0.220 | 3.9 | |

| 89580055 | 30 | 70 / 40 | 1000 | 0.220 | 3.9 | |

| Part Number | Aerolith (AES) | Type | Length (mm) | Width (mm) | Height (mm) | Area (m2) | Weight (kg) |

| 89582167 | Plate | 20 | 250 | 250 | 52 | 0.063 | 4.8 |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.