Spiral Wound Absolute Rated Depth Filter Cartridge

- Innovative depth filter cartridge technology

- All-polypropylene components

- Absolute rated at >99.9% efficiency with retention ratings from 0.5 to 70 microns

- Proprietary filter media produced directly by Pall for highly consistent, reproducible performance

- Spiral wound filter cartridge free of surfactants, binders and adhesives

- Graded pore structure provides pre and final filtration in one cartridge

- Resists contaminant unloading even at high differential pressures

Performance Specifications

Filter grades1

0.5, 1, 3, 5, 10, 20, 40, 70 μm

Maximum differential pressure

1.0 bard @ 82°C (15 psid @ 180°F)

5.2 bard @ 20°C (75 psid @ 68°F)

NOTE: Heavy wall center core option is recommended for applications where the operating temperature exceeds 52°C (125°F).

Recommended change-out differential pressure2

2.4 bard (35 psid)

Food and water contact use

Please contact Pall Corporation to verify that the product conforms to your national legislation and/or regional regulatory requirements for water and food contact use.

Rinse-up

Rinse-up to 18 Megohm-cm with a minimum of throughput.

Purity

Cartridges are free of surfactants, resins, binders, and adhesives.

Chemical compatibility

Poly-Fine ARD Series filter cartridges are compatible with a broad array of fluids. Consult the factory for specific compatibility information.

Sanitizing agents

Cartridge may be sanitized in place with common oxidizing agents. Consult the factory for compatibility information.

Product Specifications

Materials of construction

| Filter media: | Polypropylene |

| Hardware: | Polypropylene |

| Support material: | Polypropylene |

| Netting: | Polypropylene |

| Gaskets/O-rings: | Silicone elastomer, EPDM, nitrile, fluorocarbon elastomer, expanded PTFE, FEP encapsulated silicone, white silicone, white nitrile, white neoprene, Santoprene3 (DOE only), FEP encapsulated fluorocarbon elastomer |

Dimensions (nominal)

| Outside diameter: | 6.6 cm (2.6 in) |

| Lengths: | 10.2 cm (4 in), 24.8 cm (9.75 in), 25.4 cm (10 in), 49.5 cm (19.5 in), 50.8 cm (20 in), 74.3 cm (29.25 in), 76.2 cm (30 in), 99.1 cm (39 in), 102 cm (40 in) |

1- >99.9% retention rating by ASTM F-795 test.

2- Provided that the maximum differential pressure is not exceeded based on temperature limits defined above.

3- Registered trademark of Advanced Elastomer Systems.

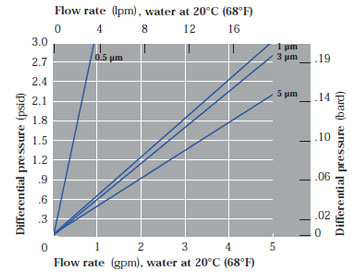

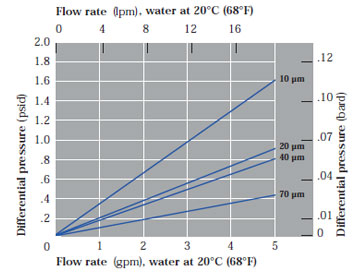

Typical Flow vs. Differential Pressure for Application Sizing3

Unit conversion: 1 bar = 100 kPa

3- Flow rate is for a 25.4 cm (10 in) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

ARD ■ - ● ▐ ♦ - ▼ (e.g., ARD 10–10US–M3)

| Code ■ | Filter Grades |

| 0.5 | 0.5 μm |

| 1 | 1 μm |

| 3 | 3 μm |

| 5 | 5 μm |

| 10 | 10 μm |

| 20 | 20 μm |

| 40 | 40 μm |

| 70 | 70 μm |

| Code ● | Cartridge Lengths cm/in (nominal) |

| 4 | 10.2 (4) |

| 9.75 | 24.8 (9.75) |

| 10 | 25.4 (10) |

| 19.5 | 49.5 (19.5) |

| 20 | 50.8 (20) |

| 29.25 | 74.3 (29.25) |

| 30 | 76.2 (30) |

| 39 | 99.1 (39) |

| 40 | 102 (40) |

| Code ▐ | Center Core |

| U | Polypropylene (standard) |

| HW | Heavy wall polypropylene (except 0.5 μm) |

| Code ♦ | Gasket/O-ring Materials5 |

| S | Silicone |

| N | Nitrile |

| E | EPDM |

| V | Fluorocarbon elastomer |

| T | Expanded PTFE (gaskets) FEP encapsulated silicone (O-rings) |

| M | White silicone |

| W | White nitrile |

| Z | White neoprene (gaskets) |

| F | FEP encapsulated fluorocarbon elastomer (O-rings) |

| Code ▼ | End Configurations |

| 1X | DOE, 2.54 cm (1 in) extended core |

| M3 | SOE flat closed end, external 222 O-rings (retrofits other manufacturers’ Code 0)4 |

| M3H | SOE large diameter closed end, external 222 O-rings |

| M4 | SOE fin end, external 222 O-rings with locking tabs (silicone and EPDM O-rings only) |

| M5 | DOE, internal 120 O-rings (retrofits 213 O-ring style)4 |

| M6 | SOE flat closed end, external 226 O-rings (retrofits other manufacturers’ Code 6)4 |

| M7 | SOE fin end, external 226 O-rings (retrofits other manufacturers’ Code 7)4 |

| M8 | SOE fin end, external 222 O-rings (retrofits other manufacturers’ Code 5)4 |

| M10 | DOE, internal O-rings (fits other manufacturers’ housings)4 |

| M11 | SOE flat closed end, internal 120 O-ring (retrofits other manufacturers’ X style)4 |

| M18 | SOE flat closed end, external 222 O-ring |

| M20 | SOE with internal O-rings (same as M10), closed end with deep recess |

| DOE | DOE with elastomer gasket seals and end caps |

| H21 | DOE, Santoprene gasket seal |

5- Leave blank if ordering H21 end configuration.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.