High Capacity Sterile Air Membrane Cartridges

The Pall Emflon PFW Final Air Filters are designed for fermenter inlet air and exhaust venting, sterile process air and sterile venting of tanks in food processes.- Pall PTFE membranes

- Inherently hydrophobic

- High flow / low pressure drop

- 100% of bacteria retention, at 0.2 μm, in liquids and gases

- Virus retentive in gases

- Melt-sealed construction

- Enhanced steaming resistance

- 100% Forward Flow tested

- Water intrusion testable

- ISO 9000 Certified Quality System

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance at .

Materials of Construction

- Membranes: Double layer PTFE

- Support/Drainage: Polypropylene, oxidation resistant

- Core/Cage/End Caps/Adaptors: Polypropylene, oxidation resistant

- Code 7 Adaptor with Encapsulated Stainless Steel Reinforcing Ring

- O-rings: silicone1

Removal Ratings

- Air/Gases: >0.003 μm, particulate2

- Liquids: 0.2 μm, sterilizing3

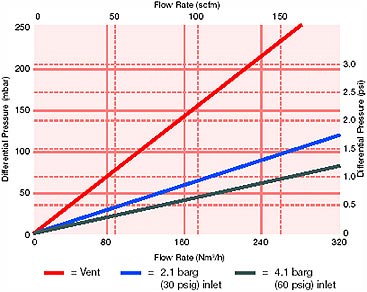

Typical Air Flow Rates

Typical initial clean medium  P per 254 mm (10 in.) element, air at 20°C (68°F). For multi-element cartridges, divide pressure drop by number of 254 mm (10 in.) elements. Non-linear cartridge turbulence factors are incorporated into housing pressure drop values. For complete assembly pressure drop, add filter cartridge medium value to housing value at specified flow rate. For gases other than air or nitrogen, contact your local Pall distributor.

P per 254 mm (10 in.) element, air at 20°C (68°F). For multi-element cartridges, divide pressure drop by number of 254 mm (10 in.) elements. Non-linear cartridge turbulence factors are incorporated into housing pressure drop values. For complete assembly pressure drop, add filter cartridge medium value to housing value at specified flow rate. For gases other than air or nitrogen, contact your local Pall distributor.

Note: Curve labels denote inlet pressures.

Integrity Test Values

- Per 254 mm (10 in.) Cartridge: 4 Forward Flow (air test gas): 60:40 IPA : Water wet (v:v)

15 cc/min at 1040 mbar (15 psi)

15 cc/min at 1040 mbar (15 psi)

Configurations (AB Code 7)4

- Single open ended

- Double 226 O-ring adapter

- Finned end, bayonet lock.

Dimensions (Nominal)

- Lengths: 254 mm (10 in.), 508 mm (20 in.), 762 mm (30 in.)

- Diameter: 70 mm (2.75 in.)

Filter Area (Nominal)

- 0.8 m2 (8.6 ft2) per 254 mm (10 in.) element

Operating Conditions

- Max. Differential Pressure/Temp 5 :

5.3 bar 8 (77 psid) at 20 °C (68 °F)

4.1 bar (60 psid) at 80 °C (176 °F) - Typical Continuous Air Service Life 6 : 12 months to 60 °C (140 °F)

- Typical Vent Service Life: 6 months to 80 °C (176 °F)

Autoclave/Steaming

- Cumulative Steaming Time 7 : 165 hrs (1hr cycles) to 140 °C (284 °F)

- Max. Forward Steaming Conditions:

1.0 bard 8 (14.5 psid) at 125 °C (257 °F)

0.3 bard (4.4 psid) at 142 °C (287.6 °F) - Max. Reverse Steaming Conditions:

0.5 bard (7.3 psid) at 125 °C (257 °F)

0.2 bard (3.0 psid) at 142 °C (287.6 °F)

1Other polymers available.

2By NaCl CNC particle analysis. Also retains 100% of Brevundimonas diminuta bacteria, bacteriophage and virus aerosols.

3Lot samples of assemblies retain >107 cfu/cm2 of Brevundimonas diminuta in liquid per mod. ASTM F838-83 and FDA guidelines.

4Contact Pall for multi-element values.

5In air/N2 service or other compatible gases.

6For continuous air flow above 60°C, Emflon PFW filters are recommended. Emflon PFW can be operated at higher temperatures for shorter time periods.

7Lab tests to establish multi-cycle resistance. Filters should be qualified in actual use. Contact Pall for recommended procedures.

8 1 bar = 100 kPa

Bottled Water, Bottled Water

Filter Cartridges

| Part No. | Description |

| FA71RPFWH4 | 254 mm (10 in.) |

| FA72RPFWH4 | 508 mm (20 in.) |

| FA73RPFWH4 | 762 mm (30 in.) |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.