20 micron

12.7 cm / 5 in

EA

1

30 micron

76.2 cm / 30 in

EA

12

5 micron

99.1 cm / 39 in

EA

12

30 micron

49.5 cm / 19.5 in

EA

1

50 micron

102 cm / 40 in

pkg

1

1 micron

75.6 cm / 29.75 in

EA

1

3 micron

102 cm / 40 in

EA

12

20 micron

24.8 cm / 9.75 in

EA

1

10 micron

76.2 cm / 30 in

EA

12

75 micron

24.8 cm / 9.75 in

EA

36

10 micron

74.3 cm / 29.25 in

EA

1

50 micron

102 cm / 40 in

EA

36

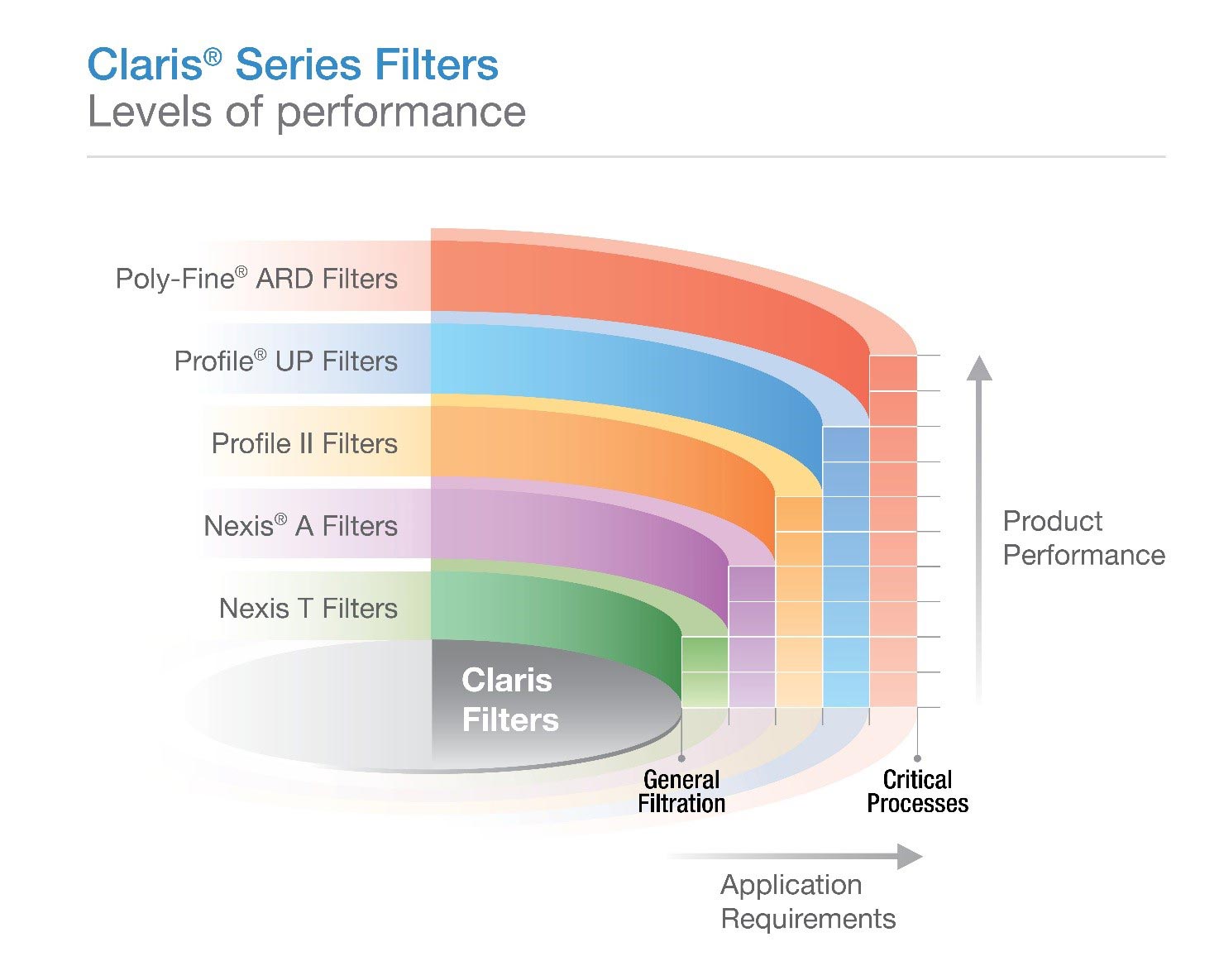

Claris® Series Filter Cartridges

An innovative extruded core provides a low-cost alternative to molded cores, without compromising filter strength or media depth.

Multiple fiber zones created by a proprietary and highly automated melt-blowing process result in a consistent and graded pore structure. The different pore sizes allow for the efficient capture of various sized particles and maximum usage of the filter's depth.

Combined, these features provide a long life,

| Features | Benefits | |||

| CoLD® Technology Manufacture | ||||

| Enhanced mechanical strength to increase resistance to media |

||||

| Melt blown depth media with graded pore structure |

Efficient capture of various particle sizes, maximizing the usage of the entire filter's depth |

|||

| Thermally bonded fibers | Consistent filtration performance | |||

| High void volume | Long service life due to high dirt holding capacity |

|||

| High strength extruded core | Enables economy without compromising flow or cartridge stability Broad chemical compatibility, suitable for use in a variety of fluids |

|||

| All polypropylene construction, without adhesives, binders or surfactants |

Broad chemical compatibility, suitable for use in a variety of fluids |

|||

Quality

- Cartridges produced in a controlled environment

- Manufactured within a Quality Management System certified to ISO 9001:2008

Materials of Construction

| Component | Description |

| Filter Medium | Polypropylene |

| Core, Fin End |

Polypropylene |

| SOE Style Cartridges only | |

| Adaptor | Polypropylene |

| O-ring Seal | Silicone Elastomer Ethylene Propylene Rubber |

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure2 | Operating Temperature |

| 1.72 bard (25 psid) | 60 °C (140 °F) |

| 3.45 bard (50 psid) | 20 °C (68 °F) |

1Fluids which do not swell, soften, or adversely affect any of the filter components

2Recommended change-out differential pressure is 2.4 bard (35 psid), provided the maximum differential pressure (based on temperature) is not exceeded.

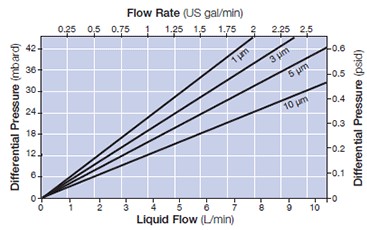

Flow Rates 3

3 Typical initial clean Δp for a 254 mm (10

This information is a guide to the part numbering structure and possible options. For availability of specific options, please contact Pall. Refer to Pall for housing details.

Part Number: CLR - [1] - [2] [3] [4]

Example Part Number: CLR510M7WS480 See bold reference codes in tables.

Table 1: Removal Rating

| Code | Description |

| 1 | 1 μm |

| 3 | 3 μm |

| 5 | 5 μm |

| 10 | 10 μm |

Table 2: Length

| Code | Description |

| DOE Style only: | |

| 5 | 127 mm (5") |

| 975 | 248 mm (9.75") |

| 9875 | 251 mm (9.875") |

| 10 | 254 mm (10") |

| 195 | 495 mm (19.5") |

| 20 | 508 mm (20") |

| 2925 | 743 mm (29.25") |

| 295 | 749 mm (29.5") |

| 30 | 762 mm (30") |

| 39 | 991 mm (39") |

| 40 | 1016 mm (40") |

| 50 | 1270 mm (50") |

| SOE Style only: | |

| 10 | 254 mm (10") |

| 20 | 508 mm (20") |

| 30 | 762 mm (30") |

| 40 | 1016 mm (40") |

Table 3: Adaptor

| Code | Description |

| blank | DOE with no endcaps |

| M3 | SOE - single open end with flat closed end and external 222 O-rings |

| M6 | SOE - single open end with flat closed end, 2 locking tabs and external 226 O-rings |

| M7 | SOE - single open end with fin end, 2 locking tabs and external 226 O-rings |

| M8 | SOE - single open end with fin end and external 222 O-rings |

Table 4: O-ring Seal Material4

| Code | Description |

| S | Silicone Elastomer |

| E | Ethylene Propylene Rubber |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.