Keeping fluids cleaner, longer, for greater value

Coralon filters represent a significant advancement in equipment protection and are a direct replacement (same form, fit, and function including fluid and temperature compatibility) for current Ultipor filter elements.Features

- Direct replacement for Ultipor elements

- Advanced pack design

- Stress-resistant media technology

- Out-to-in flow path*

* except for in-tank filter options

| Element Collapse | |

| Pressure Rating: | 10 bard (150 psid) minimum for Coreless Ultipor filter elements (polymer end caps) and for use in filters with bypass 20 bard (300 psid) minimum for Ultipor filter elements (metal end caps and core) and for use in filters with bypass 210 bard (3,045 psid) minimum for Ultipor high strength filter elements (metal end caps and core) and for use in filters without bypass |

| Temperature Range | |

| Fluorocarbon: | -29 °C (-20 °F) to +120 °C (+250 °F) |

| Nitrile: | -43 °C (-45 °F) to +120 °C (+250 °F) |

| Note : | Maximum 60°C (140°F) in water based fluids |

| Seals: | Fluorocarbon or nitrile |

| Fluid Compatibility: | Compatible with petroleum oils, water glycols, water-oil emulsions, and high water containing fluids. |

| Filter Element Hardware: | Cored filters elements - Corrosion protected end caps and core Coreless filters elements - Polymer end caps only |

All Coralon filter elements are manufactured by Pall to exacting procedures and strict quality controls. Elements are validated to the following ISO test protocols :

- Filter Ratings:

- Cyclic Stabilization Test (80% Δp ) based on SAE ARP4205. For ISO Code ratings, see Table 1

- ßx(c)≥1000 multi-pass filter ratings (per ISO 16889)

- Element Collapse Pressure Rating (ISO 2941)

- Fluid Compatibility (ISO 2943)

- Flow vs. Pressure Drop (ISO 3968)

- Flow Fatigue (ISO 3724)

- Fabrication Integrity (ISO 2942)

Innovative Media Performance

Pall’s new series of hydraulic & lube filter elements feature SRT (stress-resistant technology) media for unsurpassed performance and value. Coralon elements provide:- Low element pressure drop for small envelope size and long life

- Optimum performance under system stresses at all stages of filter life for consistently cleaner fluid

- Anti-static options to prevent electrostatic charging and potential varnish formation

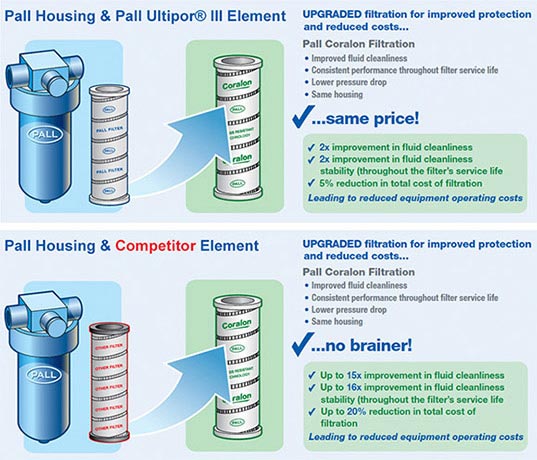

In addition to improved performance, what differences will I see?

- Coralon filters upgrade Pall Ultipor III, Ultipor III Coreless, Ultipor Dirt Fuse, Ultipor SRT, Ultipor Plus, Ultipor Max, and Red1000 elements in all standard medium grades (Z, P, N, S, T).

- The new elements will have a medium code of "C" in place of existing "U", "D", "K" "M" or "X" code in the current filter element part number; see examples in the adjacent table.

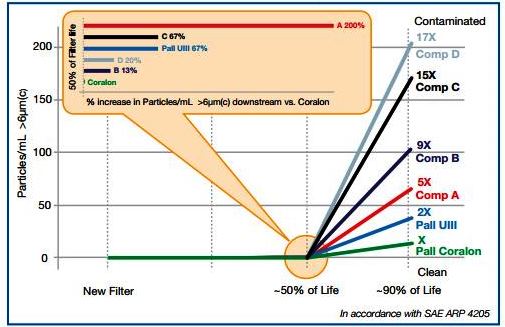

Measuring Filter Performance - the Cyclic Stabilization Test (based on SAE ARP4205):

Conditions such as varying flow, cold starts, shock and vibration can potentially reduce the effectiveness of a filter in an operating system.The Cyclic Stabilization Test examines the effects of cyclic flow conditions and dirt loading on the capture and retention characteristics of the filter. The result is an improved filter performance reporting method that simply tells the user via ISO Codes (see Table 1) the level of contamination control that can be maintained throughout the filter’s service life.

To upgrade to Coralon, replace the media code reference U, D, K, M or X with the letter C.

Table 1 - Filter Performance Ratings

| Coralon Filter Grade | ßx(c) ≥ 1000 per ISO 16889 | ISO Code Rating per Stress- Resistance Test (80% Δp )* |

| CZ | 3 | 10/08/03 |

| CP | 5 | 12/09/07 |

| CN | 7 | 14/11/06 |

| CS | 12 | 15/11/06 |

| CT | 22 | 16/14/08 |

* based on 60 psid terminal pressure drop

The Coralon Filter Performance Advantage

A critical measure of a filter’s performance is its ability to sustain fluid cleanliness throughout its service life.This graph compares a Coralon 7μm(c) rated filter to an Ultipor III filter and four competitors’ products with equivalent ratings.

Only Coralon filters produce sustained fluid cleanliness over the full life of the filter.

Steam Plants, Combined Cycle Plants, Nuclear Plants, Nuclear Plants, Gas Turbines, Gas Turbines, Gas Turbines, Steam Plants, Renewables, Renewables, Combined Cycle Plants, Combined Cycle Plants

Filter Cartridges

Examples of new filter element part number

| Existing number | New number |

| HC9600FKP8Z | HC9600FCP8Z |

| HC9601FDP13Z | HC9601FCP13Z |

The part number is printed on the bottom endcap of the filter element

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.