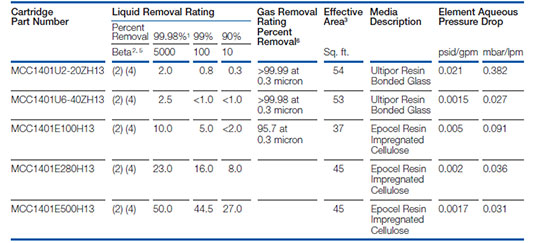

The MCC1401 filter cartridge is available in two basic types of media; Epocel® – which is a resin impregnated cellulose, and Ultipor® – a resin bonded glass fiber. These absolute rated media, specifically engineered, are available in varying grades with defined removal efficiencies and can provide up to 54 square feet of effective filtering surface area assuring long service life. See Table 1 for removal ratings of each medium type.

Operating Characteristics

MCC1401 cartridges are of pleated design, supported internally by a steel core and protected externally by steel endcaps, providing positive sealing via an internal O-ring. The maximum recommended changeout differential pressure is 60 psid/4.13 bar at 275°F/135°C.

Filter Media Characteristics

Ultipor Filter Cartridges: These cartridges are ruggedly built using a resin bonded glass fiber medium. The inert resin bonding ensures that the filters are free from media migration and establishes a permanent, fixed pore construction that prevents unloading of trapped contaminants. Because of their high effective filter area and optimized construction, Ultipor elements provide high dirt holding capacity, low clean pressure drop, long service life and low cost per gallon of fluid processed.

Epocel Filter Cartridges: This filter medium is comprised of a resin impregnated cellulose medium. Utilizing the resin impregnation technique locks the cellulose fibers in place preventing flexing or shifting, which can change the size of the flow passages and reduce removal efficiency. Epocel medium is compatible with many fluids including fresh and produced water, acids, solvents, brines, hydrocarbons, alcohols, and many others. Epocel cartridges are available in grades ranging from 10 micron up to 50 micron absolute.

Fluid Processing: Solvents, acids, chemicals, hydrocarbons, water and other fluids used in refinery, chemical and petrochemical processing always carry some harmful particles that must be removed. MCC1401 cartridges provide the fine filtration necessary to adequately clean up these fluids. Their durability, large amount of filtration area and high dirt capacity have proven to be most beneficial for this type of filtering.

High Pressure Gas Streams: Finer grades of the MCC1401 cartridge, offered for use in gas systems, will remove over 99.98% of all solid aerosols suspended in a gas stream. The effluent gas, produced after Pall filtration, will not plug sensitive instruments or foul critical machine components such as a compressor or turbine blades.

High Pressure Water Injection and Disposal: The MCC1401 high pressure filter cartridge provides reproducible high quality injection fluids for your waterflood and enhanced oil recovery operation. Injecting high quality fluids reduces formation damage, maintains stable injection profiles, and increases sweep efficiency that lowers operating expenses because of less frequent workovers.

Housing Information

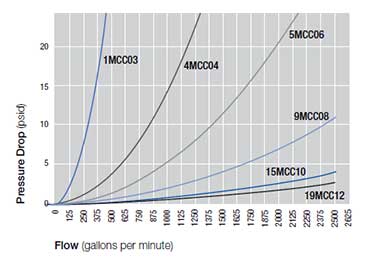

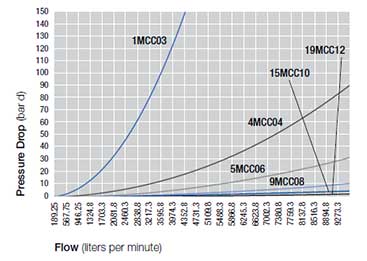

A full line of standard and special MCC1401 housings, which are designed and built to the ASME code, are available. Refer to Table 2 and Figure 1 for more information.

Table 2. Standard MCC1401 Housings – Carbon Steel, Rated at 285 psig/19.6 bar and 100°F/37° C

| Part Number | Number of Filters |

Nominal Vessel Diameter in/mm |

Inlet/Outlet Flange Size in/mm |

Housing Height in/mm |

Housing Weight (empty) lb/kg |

Housing Weight (full) lb/kg |

|||

| 1MCC0603F1285 | 1 | 6.625 / 168.3 | 3 / 76.2 | 54.25 / 1378 | 200 / 91 | 250 / 113 | |||

| 4MCC1004F1285 | 4 | 10.75 / 273.1 | 4 / 101.6 | 59 / 1498.6 | 440 / 199 | 585 / 265 | |||

| 5MCC1206F1285 | 5 | 12.75 / 323.9 | 6 / 152.4 | 64 / 1625.6 | 680 / 308 | 925 / 419 | |||

| 9MCC1608F1285 | 9 | 16 / 406 | 8 / 203.2 | 84 / 2133.6 | 1070 / 485 | 1570 / 712 | |||

| 15MCC2010F1285 | 15 | 20 / 508 | 10 / 254 | 93 / 2362.2 | 2000 / 907 | 2750 / 1247 | |||

| 19MCC2412F1285 | 19 | 24 / 609.6 | 12 / 304.8 | 110 / 2794 | 2300 / 1043 | 3500 / 1587 | |||

Table 1. MCC1401 Elements – Performance Characteristics

1Absolute Filtration Rating: The absolute rating can be operationally defined as βλ = 5000 or 99.98% removal efficiency at any given size. Note: This is the limit of the sensitivity of the rating method.

2Beta Value (β): β is the ratio of the number of particles equal to a given size or larger in the influent compared to those of the same size or larger in the effluent. β is related to the removal efficiency by:

Removal Efficiency % = |

β-1 x |

100 |

β |

3Area listed is for basic 33⁄4″ O.D. by 40″ nominal length cartridge.

4Ratings determined using 0.5 μm to 40 μm siliceous contaminant for MCC1401U2-20. For other MCC1401 cartridges, ratings determine using AC-Fine Test Dust in a water dispersion for a test system.

5Specially designed for high temperature applications.

6Per sodium chloride aerosol test. Figures are in % of particles removed at specified size or larger.

7Pressure drop in PSID per GPM for the cartridge shown. Multiply this value by the total system flow to determine the aqueous pressure drop. Next for fluids other than water, multiply this value by the fluid’s viscosity at the operating temperature in centipoise. This is the pressure drop value across the filter. It must be added to the pressure drop due to the housing. See Figures 1 and 2.

Figure 1. MCC1401 Housings – Aqueous Pressure Drop

(1) To calculate the actual housing pressure drop, multiply this aqueous pressure drop by the fluid’s specific gravity. This value must be added to the filter pressure drop to calculate the overall pressure drop of the filter system.

(1) To calculate the actual housing pressure drop, multiply this aqueous pressure drop by the fluid’s specific gravity. This value must be added to the filter pressure drop to calculate the overall pressure drop of the filter system

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.